ATH þótt standi ekki til á lager eru þær á öllum líkindum til. Hafið samband við veladeild@falkinnismar.is fyrir upplýsingar

NET WORKING TRAVEL AREA:

X-AXIS 4.000 mm

Y-AXIS 2.000 mm

Z-AXIS 180 mm

INTERNAL TANK LOADING AREA:

X-AXIS 4.275 mm

Y-AXIS 2.300 mm

OVERALL TABLE DIMENSIONS:

X-AXIS 5.250 mm

Y-AXIS 2.700 mm

Z-AXIS 1.800 mm (without H.P. tubing)

WORKING TANK HEIGHT 800 mm

MECHANICAL ACCURACY ± 0,08 mm

REPEATIBILITY: ± 0,05 mm

BALL BAR: ± 0,08 mm (300 mm diameter at 1 mt/min)

RAPID TRAVERSE SPEED:

X-Y AXIS ± 36 mt/min.

TABLE STRUCTURE:

– Internal Tubular frame for maximum strength and

stiffness

– Reinforced Machined Tubular Steel Bridge designed

to support and guarantee high rigidity against flexion,

torsion, vibration and resonance

– 4 sides complete open loading-unloading area

– Stainless Steel Tank with 8 mm MS bottom thickness

– Zero Reference square fixed on the frame

– Replaceable Galvanized slates with adjustable

reference support frame for a more accurate planarity

registrations and with central regulating pillar supports

– Removable Galvanized Steel net 30 cm under water

beneath the slates to prevent cut pieces fall to the

bottom of the tank.

– Total weight (without water): 4.000 kg

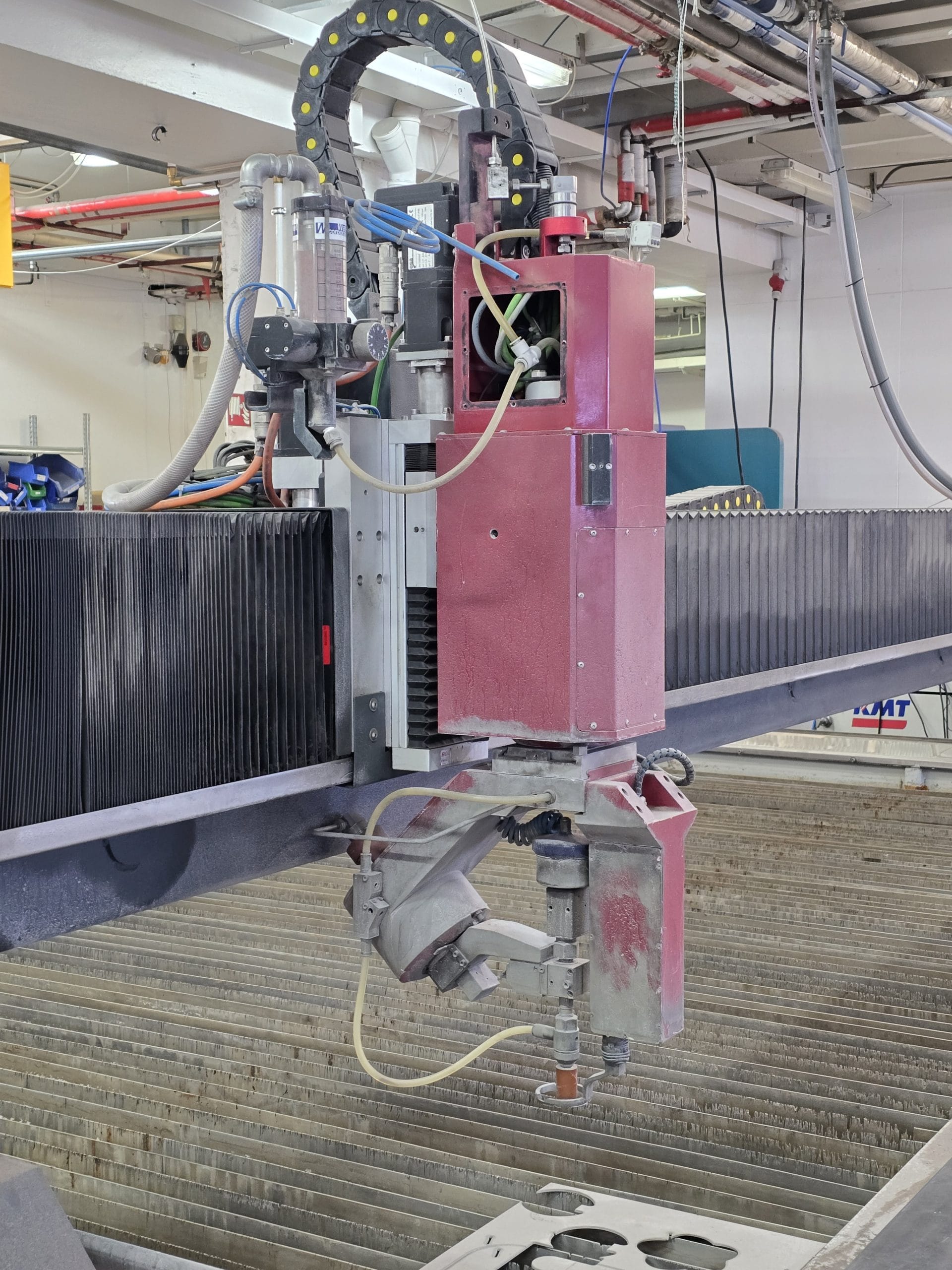

TRANSMISSIONS SYSTEM:

– Helical Hardened Rack and Pinions for X and Y axis

ALPHA WITTESTEIN (or similar quality brand)

– Ball Screw for Z axis

BOSCH REXROTH (or similar quality brand)

– Linear guideways with preloaded bearings

BOSCH REXROTH (or similar quality brand)

– Brushless motors and drivers for ALL AXIS

– Epicycloidal gear boxes < 3’ backlash

(ALPHA WITTESTEIN)

– Double Protective bellows

– Gantry system

– External Cable Chain

– Automatic Lubricating System placed on guideways

and pignons

NC NUMERICAL CONTROL

– 4 axis NC Control

– RAM 512 Mbyte

– 12” LCD Color Monitor

– Interactive Graphic simulation

– Waterproof and Dustproof Keyboard

– Digital Drivers

– Ethernet Card 10 /100

– USB port

– Stand alone Monitor support with 5 mt cable

– Electrical Cabinet connected with the frame for easy Plug&Play

– Automatic controlled acceleration and deceleration ramps

– HMI screen customized purposely for Waterjet

– Quick repositiong function after a job stop

– Mouse Pad and Infrared Mouse

– TELEASSISTANCE

PRESSURIZED ABRASIVE BULK TRANSFER

The abrasive pressurized bulk transfer continuously feeds the cutting head through a small mini-hopper and controls the correct flow of abrasive

This system is composed of:

– N. 1 Steel Abrasive Pressurized Tank…………… 300 Kg

– N. 1 Mini-Hopper next to the cutting head – Switch level control on CNC Operation Panel

– Non Return Water Valve

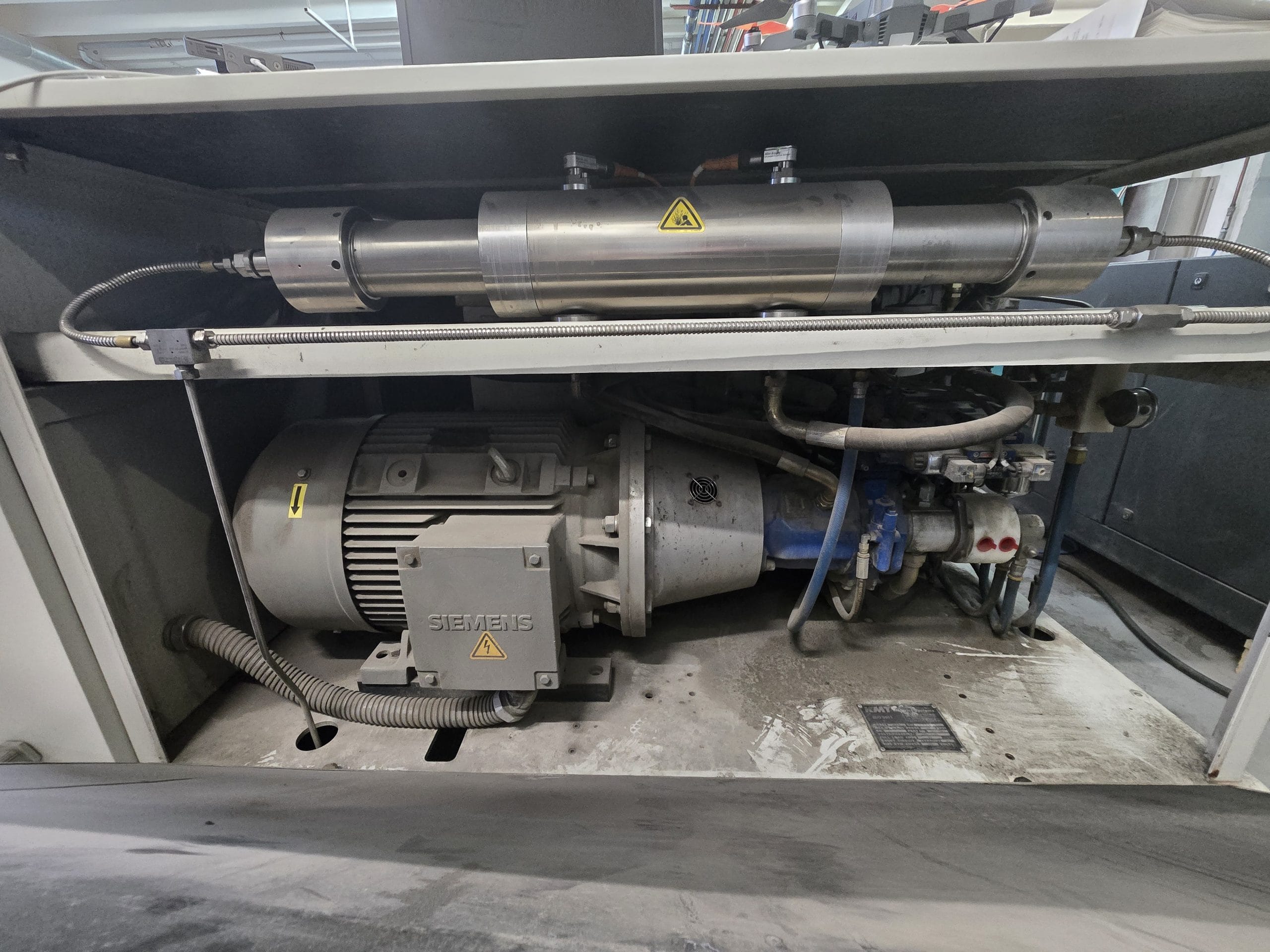

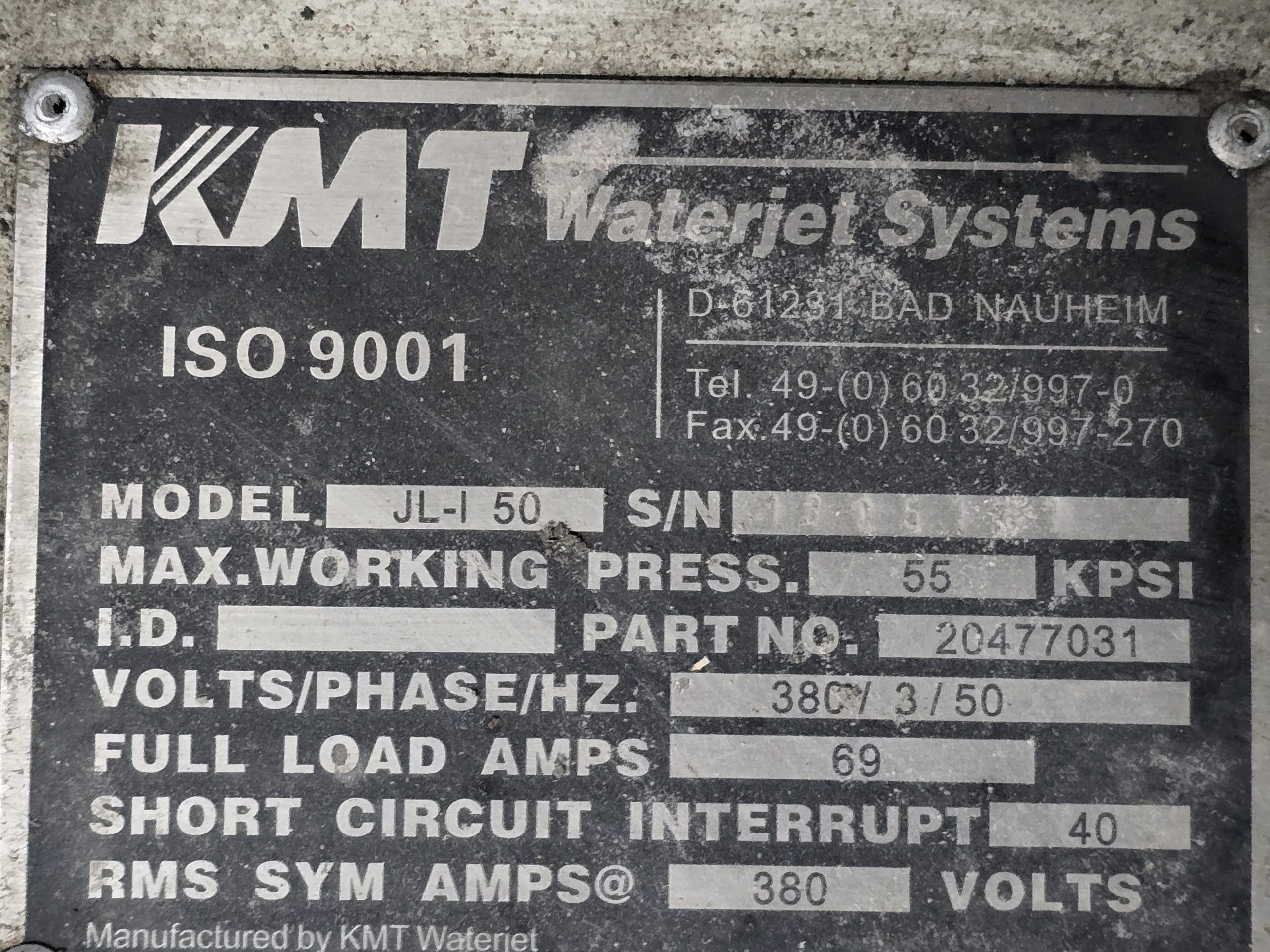

HIGH PRESSURE INTENSIFIER PUMP 50 HP

– Model 50

– Number of intensifiers 1

– Design Pressure (Bar) 4.130

– Motor Power (HP) 50

– Water consumption (Lt/min) 3.8

– Max. Orifice size (mm) 0,35

– Intensifier ratio (oil/water) 1:20

– 2 Plungers

– 1 Shock Attenuator

– 2 Low pressure water gauges

– 1 Automatic Safety Blow Down Valve (Normally Open)

– 1 Hydraulic pump

EQUIPMENTS

– 1 Water/Oil Heat exchanger

– 1 Soundproofing Pump cover

– 1 High pressure tubing set ¼” (TOTAL LENGTH = 14 mt)

– 1 Complete set of fittings and water hoses

– 1 Extended Life time HP Dynamic Seals Kit

CUTTING HEAD

– Pneumatic Valve ON/OFF (Normally Closed)

– Self-Aligning Mixing Chamber with Ruby Orifice

– 2 Focusing Tubes

– 2 Rubies

MAINTENANCE:

– 1 Maintenance tool kit

– 1 Hard Copy of Service and operation Manuals

– 1 Maintenance Video CD

POWER SUPPLY:

– 1 Electrical cabinet already built in with:

a) Plc alarms control by CNC: High Oil Temperature, Low Oil Level, Low Inlet Water Pressure, Dual (HIGH/LOW) Pressure Control, number of strokes, automatic shut down after 5 minutes of non operation.

b) Star Delta:

– Voltage (± 10 %) 400 V / 50 Hz

– Main Fuse 100 A

– Power supply 37 Kw